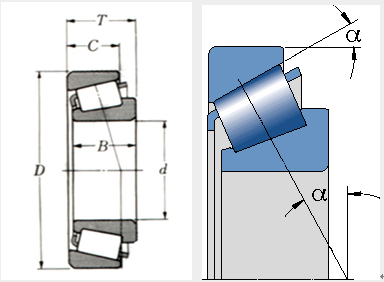

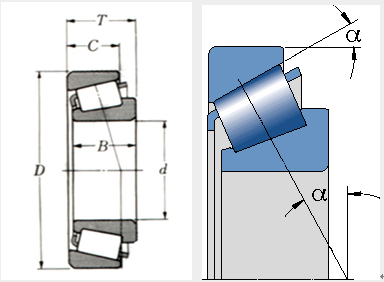

Tapered roller bearings have tapered inside track and outside track rollaway nest, and the taper rollers are ranked between them. All the projection lines of taper surface are all gathering on one point on the axes of bearings. Because of such design, taper roller bearings are especially suitable to endure compound loads, including radial load and axial load. The carrying capacity of axial load of the bearings is mainly decided by the contact angle α, the bigger α, the higher capacity of axial load. The size of angle is showed by calculation factor e, the bigger e is, the bigger contact angle, the higher capacity of axial load.

Single-Row Tapered Roller Bearings

The most basic and widely used tapered bearing, the single-row type consists of the cone assembly and the cup. It is usually fitted as one of an opposing pair. During equipment assembly, single-row bearings can be set to the required clearance (endplay) or preload condition to optimize performance.

Double-Row Tapered Roller Bearings

Double- or two-row tapered roller bearings feature double cups and two single cones. They are available in a variety of configurations for general industrial and automotive applications.

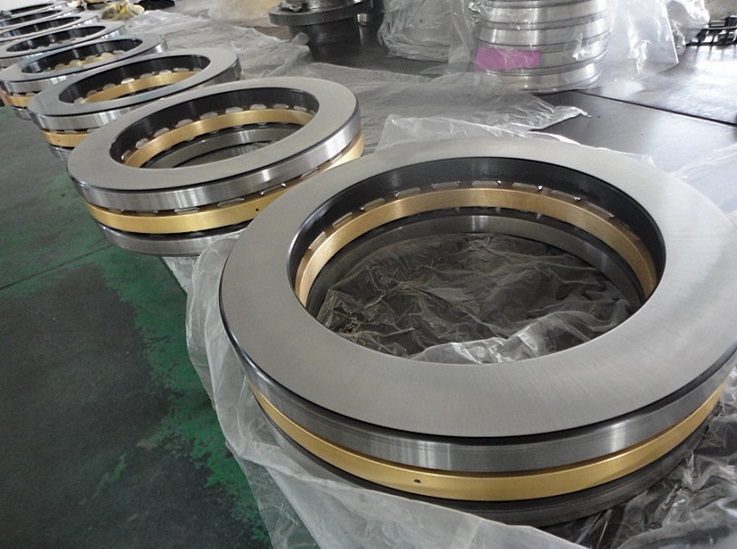

Four-Row Tapered Roller Bearings

Four-row bearings provide maximum capacity in minimum space, combining the inherent high-load, radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings.

Their main application is on the roll necks of rolling mill equipment. All four-row bearings are supplied as pre-set matched assemblies with all components identified to ensure correct installation sequence.

Tapered roller bearings (TRBs) utilize rolling elements that are shaped like a truncated cone (Figure 1), and are constructed so that all tapered surfaces converge at a common apex point on the bearing centerline to yield true rolling motion (Figure 2). Tapered roller bearings are generally used in lower speed, high load applications and are capable of absorbing radial and/or axial loads. The internal angles may be designed to tailor the bearing to the loading demands of a specific application. Tapered roller bearings are a separable two-piece design (cup and cone) (Figure 3); which, allows the end-use to optimize the internal clearance (and life) for each application when the bearing is mounted. PEER primarily manufactures single row (TS), sealed single row (LA), and matched set tapered roller bearings.

Taper roller bearings can endure radial and axial combined load, mainly is radial load. The carrying capacity of bearings is decided by the angle of rolloway nest in outside track, the bigger contact angle, the greater amount of carrying capacity. Consumers need to adjust the clearance of single row taper roller bearings during installing, the clearance of double row and four row tapered roller bearings already been booked according to consumers requirement when goods leave factory, so consumer no need to adjust it.

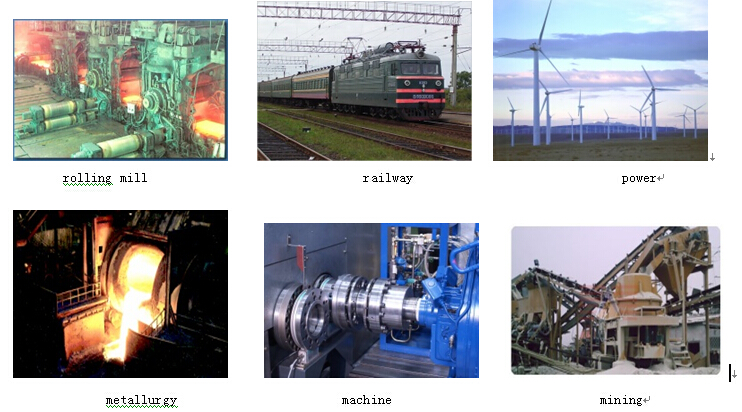

Application: Tapered roller bearings are widely used in auto, rolling mill, mine, metallurgy, plastic machinery and so on.

PDF Download

PDF Download